Urethane Cement Flooring Systems

Superior Durability and Chemical Resistance for Demanding Environments

The Ultimate Floor for Durable and Manufacturing Needs

Urethane Cement Flooring Systems

Superior Durability & Chemical Resistance for Demanding Environments

The Ultimate Floor for Durable and Manufacturing Needs

Urethane Cement Floors

Urethane cement flooring is a high-performance solution that combines polyurethane and cementitious components to create a seamless, durable surface. Designed to withstand extreme conditions, it is ideal for industries requiring robust flooring systems that can endure thermal shock, chemical exposure, and heavy traffic.

Key Benefits of Urethane Cement

Exceptional resistance to chemicals, including acids, alkalis, and solvents

Superior durability under heavy mechanical stress and abrasion

Thermal shock resistance, suitable for environments with rapid temperature changes

Seamless, non-porous surface that is easy to clean and maintain

Excellent moisture tolerance, allowing installation over green concrete

Deep Dive Into Urethane Cement

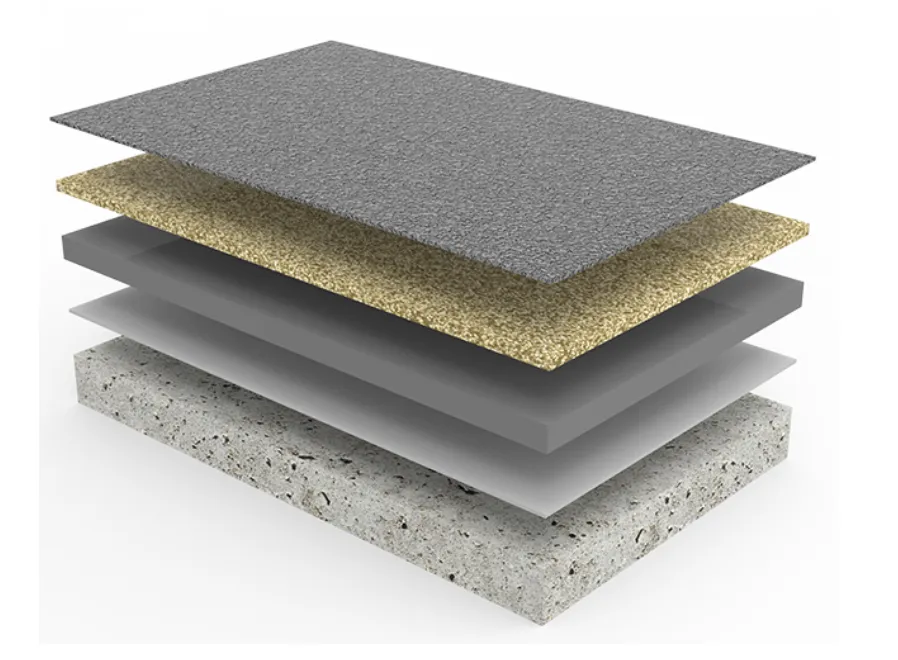

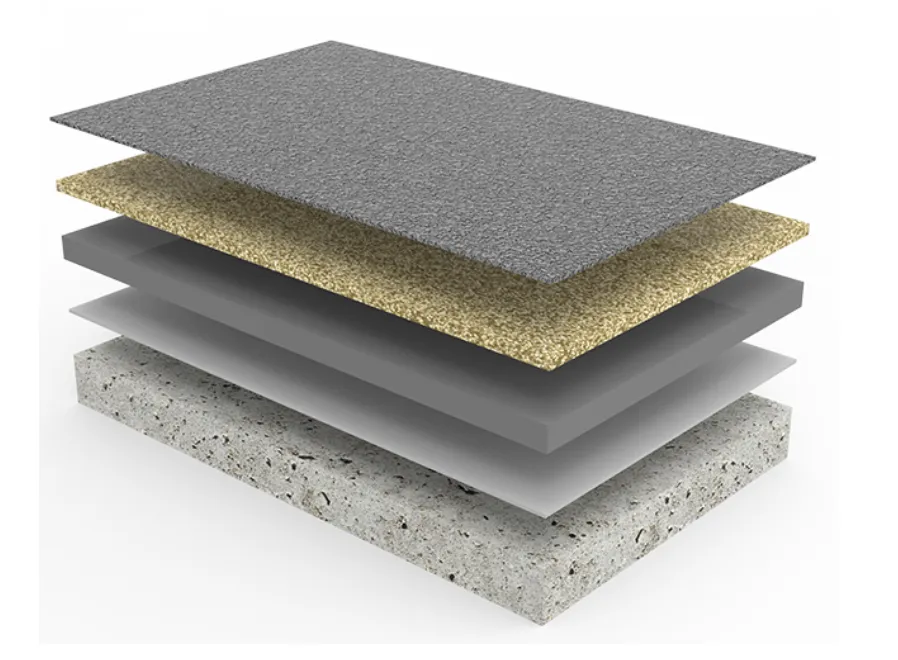

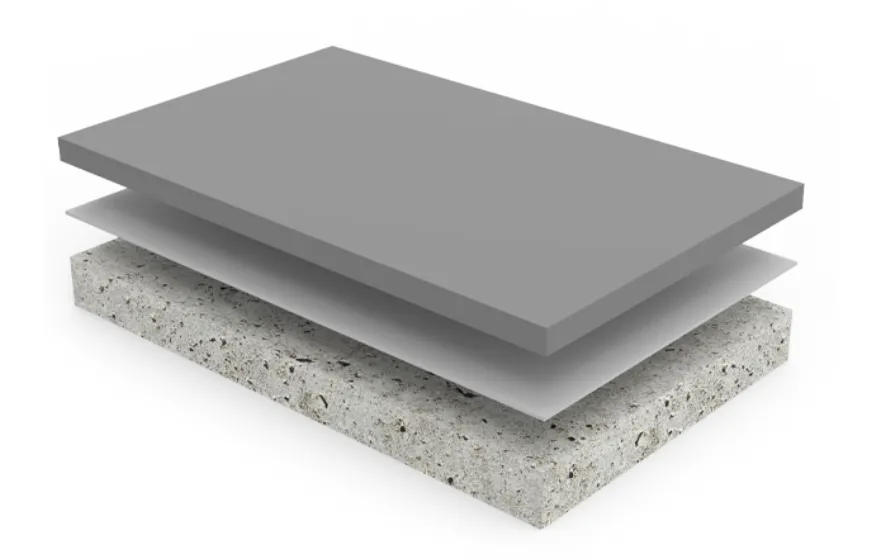

System Components

Primer: Enhances adhesion between the substrate and the urethane cement layer.

Urethane Cement Base Coat: A blend of polyurethane resin, Portland cement, aggregates, and other fine materials that form the primary layer.

Topcoat (Optional): Provides additional protection and can be customized for slip resistance or aesthetic preferences.

Technical Specifications

Thickness: Typically installed at 1/8 to 1/4 inch thickness, depending on application requirements.

Compressive Strength: High compressive strength suitable for heavy-duty applications.

Thermal Resistance: Can withstand temperatures ranging from -330°F to +240°F, making it ideal for areas subjected to extreme temperature variations.

Suitable Environments

Food and beverage processing facilities

Commercial kitchens

Pharmaceutical and chemical processing plants

Warehouses and distribution centers

Manufacturing facilities

Cold storage areas

Deep Dive Into Urethane Cement

System Components

Primer: Enhances adhesion between the substrate and the urethane cement layer.

Urethane Cement Base Coat: A blend of polyurethane resin, Portland cement, aggregates, and other fine materials that form the primary layer.

Topcoat (Optional): Provides additional protection and can be customized for slip resistance or aesthetic preferences.

Technical Specifications

Thickness: Typically installed at 1/8 to 1/4 inch thickness, depending on application requirements.

Compressive Strength: High compressive strength suitable for heavy-duty applications.

Thermal Resistance: Can withstand temperatures ranging from -330°F to +240°F, making it ideal for areas subjected to extreme temperature variations.

Suitable Environments

Food and beverage processing facilities

Commercial kitchens

Pharmaceutical and chemical processing plants

Warehouses and distribution centers

Manufacturing facilities

Cold storage areas

Urethane Cement Application Process

Step by Step Guide

Surface Preparation: Thoroughly clean and prepare the concrete substrate to ensure it is free from contaminants, oils, and debris.

Primer Application: Apply a suitable primer to promote adhesion between the substrate and the urethane cement layer.

Mixing: Combine the polyurethane resin with Portland cement, aggregates, and other additives according to manufacturer specifications.

Application: Spread the mixed urethane cement onto the primed surface using trowels or squeegees to achieve the desired thickness.

Finishing: Optional broadcast of aggregates or application of a topcoat to achieve the desired surface texture and slip resistance.

Curing: Allow the flooring system to cure as per manufacturer guidelines before resuming normal operations.

Urethane Cement Application Process

Step by Step Guide

Surface Preparation: Thoroughly clean and prepare the concrete substrate to ensure it is free from contaminants, oils, and debris.

Primer Application: Apply a suitable primer to promote adhesion between the substrate and the urethane cement layer.

Mixing: Combine the polyurethane resin with Portland cement, aggregates, and other additives according to manufacturer specifications.

Application: Spread the mixed urethane cement onto the primed surface using trowels or squeegees to achieve the desired thickness.

Finishing: Optional broadcast of aggregates or application of a topcoat to achieve the desired surface texture and slip resistance.

Curing: Allow the flooring system to cure as per manufacturer guidelines before resuming normal operations.

Urethane Cement Projects

Frequently Asked Questions

What is urethane cement flooring?

Urethane cement flooring is a seamless, high-performance flooring system that combines polyurethane resins with cement and aggregates to create a durable and chemically resistant surface.

How does urethane cement differ from epoxy flooring?

While both provide durable surfaces, urethane cement offers superior thermal shock resistance and moisture tolerance compared to epoxy flooring, making it ideal for environments with extreme temperature changes and high moisture levels.

Is urethane cement flooring suitable for areas with heavy machinery?

Yes, urethane cement flooring is designed to withstand heavy mechanical stress and is ideal for areas with heavy machinery and equipment.

How do I maintain a urethane cement floor?

Regular cleaning with a neutral pH cleaner and periodic inspections to address any potential issues will help maintain the floor's performance and appearance.

© 2022 RC Coatings - All Rights Reserved,

© 2022 RC Coatings - All Rights Reserved,