Metallic Epoxy Flooring Systems

Elevate Your Space with Stunning, Durable Metallic Finishes

Elegance and shine that never looked so good!

Metallic Epoxy Flooring Systems

Elevate Your Space with Stunning, Durable Metallic Finishes

Elegance and shine that never looked so good!

Metallic Flooring

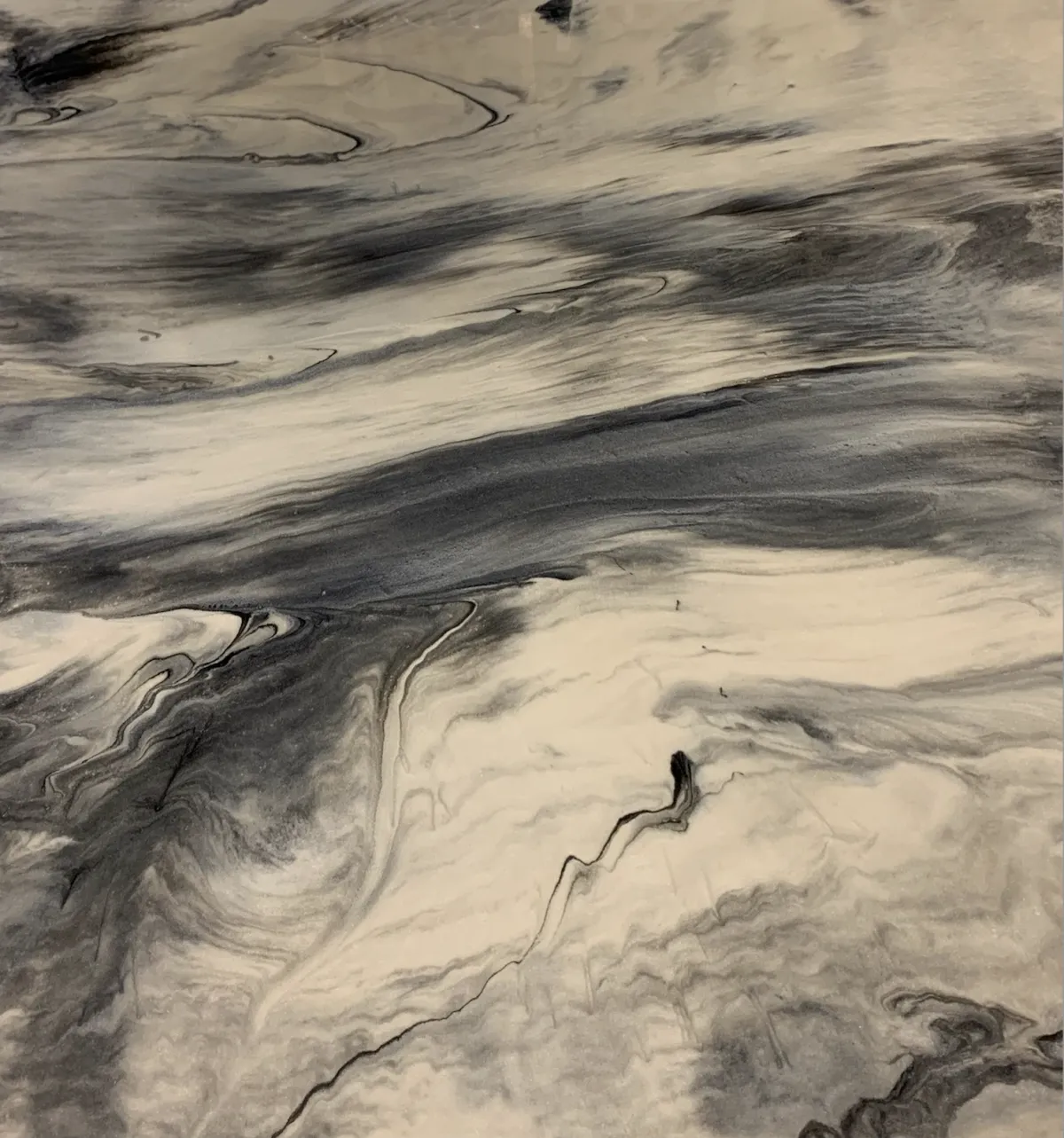

Metallic epoxy flooring systems combine high-performance epoxy resins with metallic pigments to create a unique, three-dimensional appearance. These floors offer a seamless, durable surface that enhances the aesthetic appeal of any space, making them ideal for both residential and commercial applications.

Key Benefits of Metallic Flooring

Striking visual effects with customizable colors and patterns

Seamless, non-porous surface for easy maintenance

High durability and resistance to wear

Chemical and stain resistance

Enhanced property value and appeal

Deep Dive Into Metallic Flooring

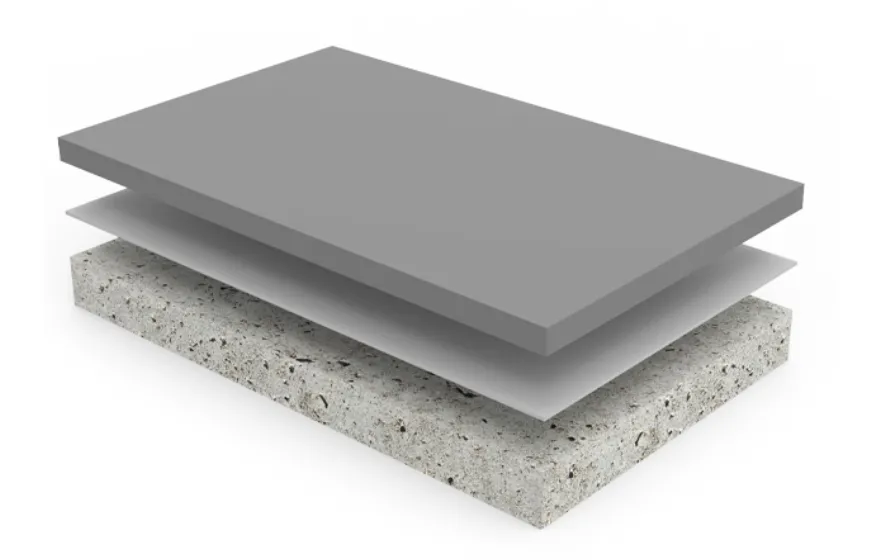

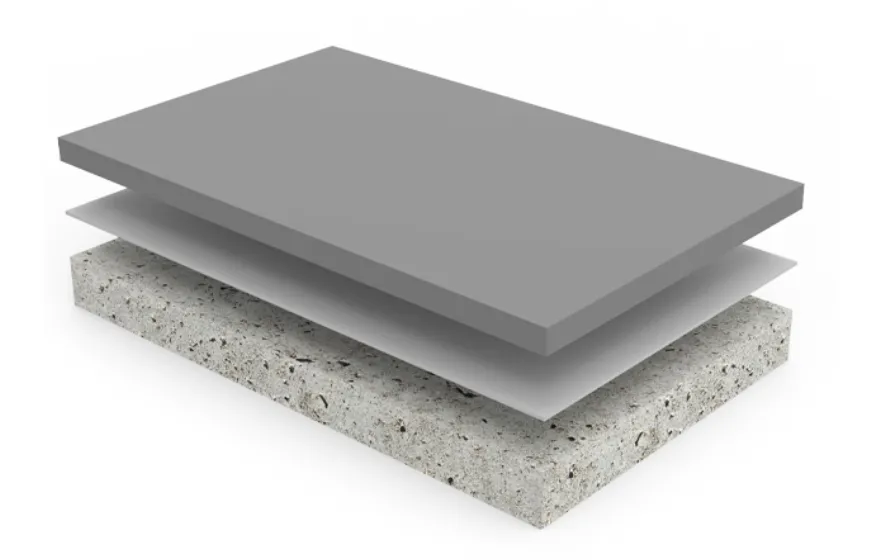

System Components

Primer Coat: Ensures strong adhesion to the substrate.

Base Coat: A pigmented epoxy layer that provides the foundation color.

Metallic Epoxy Coat: A clear epoxy mixed with metallic pigments, creating dynamic visual effects.

Topcoat: A protective layer that enhances durability and gloss.

Technical Specifications

Thickness: Typically ranges from 30 to 40 mils, depending on application requirements.

Compressive Strength: High compressive strength suitable for various applications.

Abrasion Resistance: Excellent resistance to wear, making it ideal for high-traffic environments.

Suitable Environments

Retail stores

Showrooms

Restaurants

Hotels

Residential interiors

Offices

Deep Dive Into Metallic Flooring

System Components

Primer Coat: Ensures strong adhesion to the substrate.

Base Coat: A pigmented epoxy layer that provides the foundation color.

Metallic Epoxy Coat: A clear epoxy mixed with metallic pigments, creating dynamic visual effects.

Topcoat: A protective layer that enhances durability and gloss.

Technical Specifications

Thickness: Typically ranges from 30 to 40 mils, depending on application requirements.

Compressive Strength: High compressive strength suitable for various applications.

Abrasion Resistance: Excellent resistance to wear, making it ideal for high-traffic environments.

Suitable Environments

Retail stores

Showrooms

Restaurants

Hotels

Residential interiors

Offices

Metallic Flooring Application Process

Step by Step Guide

Surface Preparation: Ensure the substrate is clean, dry, and free of contaminants.

Primer Application: Apply a primer to promote adhesion between the substrate and the epoxy system.

Base Coat Application: Apply the pigmented base coat evenly.

Metallic Epoxy Application: Pour and manipulate the metallic epoxy mixture to achieve the desired effect.

Topcoat Application: Once the metallic layer has cured, apply a protective topcoat to seal the system.

Metallic Flooring Application Process

Step by Step Guide

Surface Preparation: Ensure the substrate is clean, dry, and free of contaminants.

Primer Application: Apply a primer to promote adhesion between the substrate and the epoxy system.

Base Coat Application: Apply the pigmented base coat evenly.

Metallic Epoxy Application: Pour and manipulate the metallic epoxy mixture to achieve the desired effect.

Topcoat Application: Once the metallic layer has cured, apply a protective topcoat to seal the system.

Metallic Flooring Projects

Frequently Asked Questions

What is metallic epoxy flooring?

Metallic epoxy flooring is a decorative flooring system that combines epoxy resins with metallic pigments to create a unique, three-dimensional appearance.

How durable is metallic epoxy flooring?

Metallic epoxy floors are highly durable, resistant to wear, chemicals, and stains, making them suitable for both residential and commercial applications.

Can metallic epoxy floors be customized?

Yes, these floors offer limitless design possibilities with various colors and application techniques to achieve the desired look.

How do I maintain a metallic epoxy floor?

Regular sweeping and mopping with a neutral cleaner are typically sufficient. Avoid abrasive cleaning tools to maintain the floor's glossy finish.

© 2022 RC Coatings - All Rights Reserved,

© 2022 RC Coatings - All Rights Reserved,