Methyl Methacrylate (MMA) Flooring Systems

Rapid-Curing, Durable Flooring Solutions for Demanding Environments

Take your floor to the next level in the fastest way possible.

Methyl Methacrylate (MMA) Flooring Systems

Rapid-Curing, Durable Flooring Solutions for Demanding Environments

Take your floor to the next level in the fastest way possible.

MMA Flooring

Methyl Methacrylate (MMA) flooring systems are advanced resin-based solutions known for their exceptionally fast curing times and robust performance characteristics. These systems are ideal for facilities that require minimal downtime and demand high durability, chemical resistance, and the ability to withstand varying temperatures.

Key Benefits of MMA Flooring

Rapid Cure Time: Fully cures within one hour, allowing for quick return to service and minimal operational disruption.

Temperature Versatility: Can be applied and cured in temperatures ranging from below freezing to high heat, making it suitable for environments like cold storage and commercial kitchens.

Chemical and Stain Resistance: Offers excellent resistance to a wide range of chemicals, oils, and stains, ensuring longevity in harsh environments.

Durability: High resistance to abrasion and impact, making it suitable for areas with heavy foot and vehicular traffic.

Aesthetic Flexibility: Available in various colors and finishes, including decorative options with colored quartz or flakes.

MMA Flooring

Methyl Methacrylate (MMA) flooring systems are advanced resin-based solutions known for their exceptionally fast curing times and robust performance characteristics. These systems are ideal for facilities that require minimal downtime and demand high durability, chemical resistance, and the ability to withstand varying temperatures.

Key Benefits of MMA Flooring

Rapid Cure Time: Fully cures within one hour, allowing for quick return to service and minimal operational disruption.

Temperature Versatility: Can be applied and cured in temperatures ranging from below freezing to high heat, making it suitable for environments like cold storage and commercial kitchens.

Chemical and Stain Resistance: Offers excellent resistance to a wide range of chemicals, oils, and stains, ensuring longevity in harsh environments.

Durability: High resistance to abrasion and impact, making it suitable for areas with heavy foot and vehicular traffic.

Aesthetic Flexibility: Available in various colors and finishes, including decorative options with colored quartz or flakes.

Deep Dive Into MMA Flooring

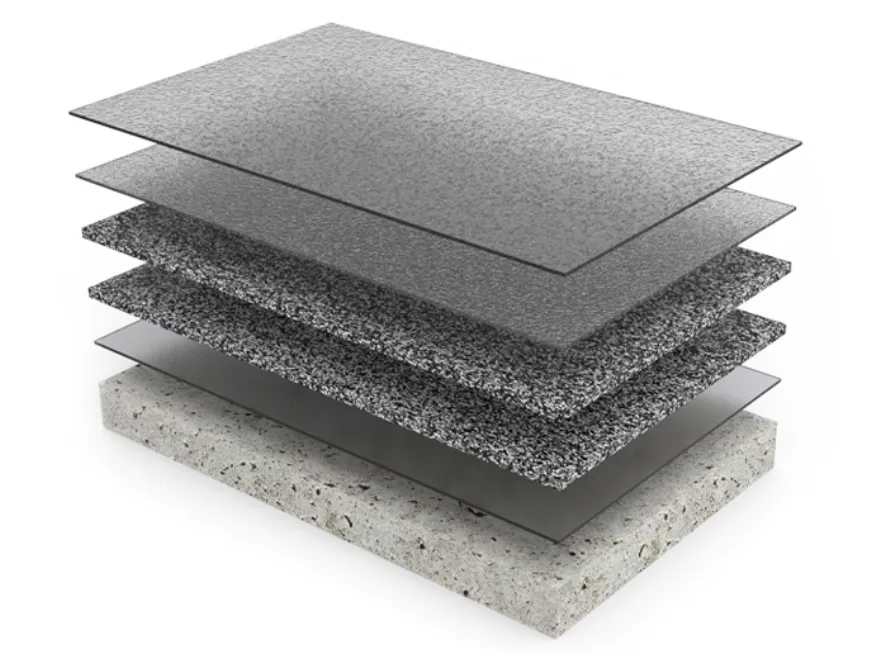

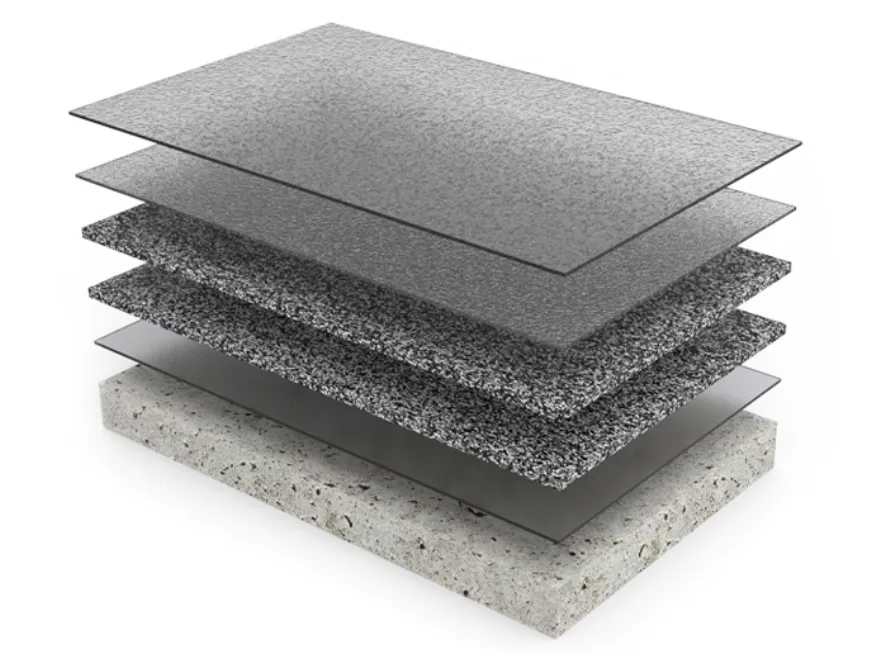

System Components

Primer: Ensures strong adhesion to the substrate, often with low viscosity to penetrate and reinforce the surface.

Body Coat: A medium-viscosity resin that can be customized with fillers or aggregates to achieve desired thickness and texture.

Topcoat: A protective layer that provides UV stability, chemical resistance, and the desired surface finish, whether glossy or matte.

Technical Specifications

Cure Time: Approximately 1 hour to full cure, depending on environmental conditions.

Application Temperature Range: From -20°F (-29°C) to over 100°F (38°C), allowing for installation in diverse environments.

VOC Content: Low VOC formulations available, complying with environmental regulations.

Suitable Environments

Food and beverage processing facilities

Commercial kitchens and restaurants

Pharmaceutical and healthcare facilities

Cold storage and freezer areas

Retail spaces

Manufacturing plants

Deep Dive Into MMA Flooring

System Components

Primer: Ensures strong adhesion to the substrate, often with low viscosity to penetrate and reinforce the surface.

Body Coat: A medium-viscosity resin that can be customized with fillers or aggregates to achieve desired thickness and texture.

Topcoat: A protective layer that provides UV stability, chemical resistance, and the desired surface finish, whether glossy or matte.

Technical Specifications

Cure Time: Approximately 1 hour to full cure, depending on environmental conditions.

Application Temperature Range: From -20°F (-29°C) to over 100°F (38°C), allowing for installation in diverse environments.

VOC Content: Low VOC formulations available, complying with environmental regulations.

Suitable Environments

Food and beverage processing facilities

Commercial kitchens and restaurants

Pharmaceutical and healthcare facilities

Cold storage and freezer areas

Retail spaces

Manufacturing plants

MMA Flooring Application Process

Step by Step Guide

Surface Preparation: Thoroughly clean and prepare the substrate to remove contaminants, repair defects, and ensure a suitable profile for adhesion.

Primer Application: Apply the MMA primer to seal the substrate and promote adhesion of subsequent layers.

Body Coat Application: Apply the MMA body coat, incorporating aggregates or fillers as specified to achieve the desired thickness and texture.

Topcoat Application: Apply the MMA topcoat to seal the system, providing chemical resistance, UV stability, and the desired finish.

Curing: Allow the system to cure for approximately one hour before resuming normal operations.

MMA Flooring Application Process

Step by Step Guide

Surface Preparation: Thoroughly clean and prepare the substrate to remove contaminants, repair defects, and ensure a suitable profile for adhesion.

Primer Application: Apply the MMA primer to seal the substrate and promote adhesion of subsequent layers.

Body Coat Application: Apply the MMA body coat, incorporating aggregates or fillers as specified to achieve the desired thickness and texture.

Topcoat Application: Apply the MMA topcoat to seal the system, providing chemical resistance, UV stability, and the desired finish.

Curing: Allow the system to cure for approximately one hour before resuming normal operations.

MMA Floor Coating Projects

Frequently Asked Questions

What is MMA flooring?

MMA stands for Methyl Methacrylate, a type of resin used in flooring systems known for its rapid curing time and durable properties.

How quickly can an MMA floor be installed?

MMA flooring systems can fully cure within approximately one hour after application, allowing for installations to be completed and returned to service rapidly.

Is MMA flooring suitable for cold environments?

Yes, MMA flooring can be applied and cured in temperatures as low as -20°F (-29°C), making it ideal for cold storage areas and freezers.

How do I maintain an MMA floor?

Regular cleaning with appropriate detergents and periodic inspections to address any wear or damage will help maintain the floor's performance and appearance.

© 2022 RC Coatings - All Rights Reserved,

© 2022 RC Coatings - All Rights Reserved,